Welcome to our FAQ section, where you will find answers to the most frequent questions about our products and services. We have designed this section to provide you with clear and concise information to help you get the most out of our product.

Yes, most firearms will benefit from a good break-in period. When you receive your firearm: read your instruction manual for a good overview of the controls and other information, ensure your firearm is unloaded, disassemble your firearm, clean, and properly lubricate it per the instructions, cycle the action a few times to ensure all parts are moving freely. Head to the range and run some high-quality ammunition through your firearm. Typically, you will see performance and reliability become consistent after the first initial uses of the firearm. Clean and lubricate as needed during break-in.

Pistols typically will need 100-300rds of ammunition, we recommend FMJ ammo for break-in.

Many aftermarket companies offer holsters specifically for the PX-9 GEN3 and PX-9 Carry Pistol. Please visit https://sdsimports.com/shop/holsters/ for available models.

Urban Carry

Be advised that PX-9 Carry models will fit into holsters designed for the PX-9 Duty and Tactical models.We have also found that some holsters designed for the Sig Sauer P320 and Springfield Xdm will work with little to no modification. Please test fitment before carrying

Below is a list of the common spring weights of our 1911 pistols.

Some models are finished with high-quality Cerakote in the following colors:

Carbon Steel models are Cerakote over Manganese Phosphate. Aluminum models are Cerakote over hardcoat anodized.

The Tisas Builder Kits require an intermediate working knowledge of gunsmithing techniques and understanding of the 1911 platform to assemble. Fitting of the frame and slide will require attention to detail and special tools or supplies. We recommend 800-grit lapping compound followed by Flitz polishing compound for fitting the frame to the slide.

Frame/Slide Lapping Info:

There are various books, videos and online resources to guide you through the process and we suggest educating yourself properly or having a competent gunsmith assist you with assembly.

Tools Required:

Finish (Cerakote, Duracoat, Gun Blue or other Finish to Protect Metal Parts)

Legal Disclaimer:

Tisas USA or SDS Imports shall not be liable for any misuse, injury or death from a improperly assembled Builder Kit 1911. Tisas USA or SDS Imports does not extend any warranty or promise to repair any modified or assembled Builder Kit 1911. Buyer and/or End-User assume all risks associated with the safety, function and subsequent dangers associated with process to build, modify or use of a Builder Kit 1911.

Below is a list of barrel twist for each caliber.

Rear: .680 Wide / .350" Height

**This applies to Tisas models with dovetail front and rear only.**

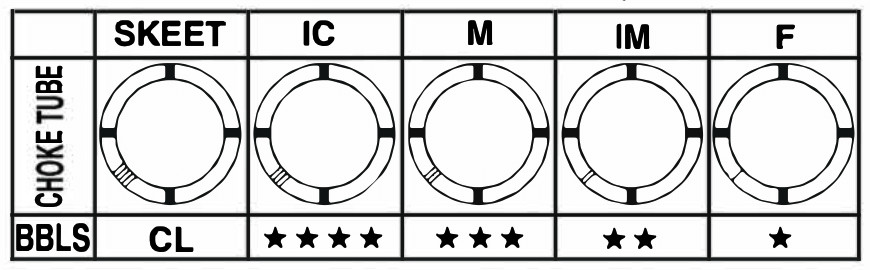

Our shotguns have internally threaded barrels that utilize Benelli/Mobil® pattern choke tubes.

Chokes can be identified by the number of notches present on the muzzle end.

The following are guideline for slecting the proper choke tube for various ammo types.

Modified/Full: Buckshot or Bird Shot.

Important Info Regarding Steel Shot

The choke (before constriction) in all modern shotguns has been established based on the pattern performance of shot shells loaded with lead shot. When using steel shot shells,you will notice a different performance in pattern density versus the established lead shot pattern, because the steel shot is harder and lighter than lead shot. You should be aware of the following differences and cautions: Never shoot steel shot loads in a full choked barrel or an improved modified choked barrel. Doing so, may cause the barrel to swell or rupture. In general, steel shot fired with a modified choke will produce the equivalent of a lead full choke pattern. This will be true of all steel shot sized up to and including no. 2. The established improved cylinder chokes will produce the equivalent of a (lead) modified pattern. All steel shot sized larger than no. 2, and including special sized such as F, T, etc, should be used only with improved cylinder chokes. These steel shot sizes, when used in an improved cylinder choke, will produce equivalent to (lead) full choke patterns. The established cylinder choke or bore will produce the equivalent of a modified (lead) pattern. Additional information concerning the use of steel shot is available from the ammunition companies. When using aftermarket choke tubes, check the mfg. recommendations prior to use.

Customizing your MAC firearm is a way to enhance the functionality and performance, but may also void your warranty, so proceed with caution. SDS Imports/MAC suggest any/all work is completed by a competent gunsmith.

MAC 1911 Single Stack Pistols

Our single stack models are built using Colt® Series 70® pattern parts, so many aftermarket options are available, minor fitting required for proper fit and function may be required.

MAC 1911 Double Stack Pistols

Customizing your MAC firearm is a way to enhance the functionality and performance, but may also void your warranty, so proceed with caution. SDS Imports/MAC suggest any/all work is completed by a competent gunsmith.

MAC 1014 Series Shotguns

MAC 1014 shotguns are compatible with most O.E.M. and aftermarket parts designed to fit Benelli® M4 series shotguns.

MAC 2 Series Shotguns

MAC 2 shotguns are compatible with most O.E.M. and aftermarket parts designed to fit Benelli® M2 series shotguns.

We do not guarantee compatibility with all parts from 3rd party manufacturers and some parts may require fitting, installation by a competent gunsmith is recommended.

To remove, loosen or tighten the stock on your MAC-1014 or MAC-2 shotgun please do the following:

MAC JSOC 1911

Tisas Pattern Dovetail Front

MAC 1911 DS Models

MAC-5 and MAC-5k Models Ship from the Mfg with the bolt gap set to the following specs:

0.25MM - 0.45MM. +/- .05MM

Please be advised that when measuring bolt gap to use a high-quality set of feeler gauges, and the firearm must be unfired, and all internal parts clean from any dirt, carbon, or fouling. Firing the weapon with Binary Triggers, Suppressed, or using Higher Velocity/Heavier Ammunition under heavy volumes of fire may cause excessive to wear internal components result bolt gap may need to be checked and adjusted by the use of +/- rollers to ensure proper function of the weapon.

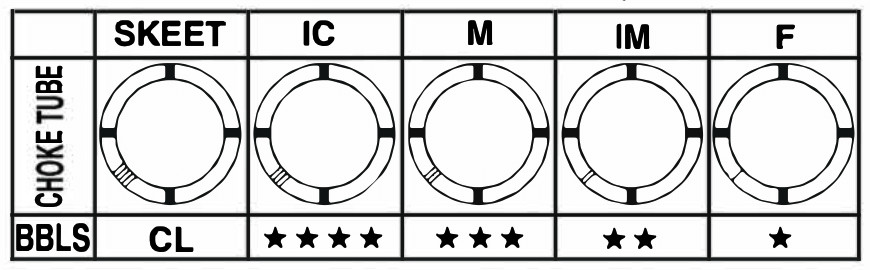

Our shotguns have internally threaded barrels that utilize Benelli/Mobil® pattern choke tubes.

Chokes can be identified by the number of notches present on the muzzle end.

The following are guideline for slecting the proper choke tube for various ammo types.

Modified/Full: Buckshot or Bird Shot.

Important Info Regarding Steel Shot

The choke (before constriction) in all modern shotguns has been established based on the pattern performance of shot shells loaded with lead shot. When using steel shot shells,you will notice a different performance in pattern density versus the established lead shot pattern, because the steel shot is harder and lighter than lead shot. You should be aware of the following differences and cautions: Never shoot steel shot loads in a full choked barrel or an improved modified choked barrel. Doing so, may cause the barrel to swell or rupture. In general, steel shot fired with a modified choke will produce the equivalent of a lead full choke pattern. This will be true of all steel shot sized up to and including no. 2. The established improved cylinder chokes will produce the equivalent of a (lead) modified pattern. All steel shot sized larger than no. 2, and including special sized such as F, T, etc, should be used only with improved cylinder chokes. These steel shot sizes, when used in an improved cylinder choke, will produce equivalent to (lead) full choke patterns. The established cylinder choke or bore will produce the equivalent of a modified (lead) pattern. Additional information concerning the use of steel shot is available from the ammunition companies. When using aftermarket choke tubes, check the mfg. recommendations prior to use.

Yes, most firearms will benefit from a good break-in period. When you receive your firearm: read your instruction manual for a good overview of the controls and other information, ensure your firearm is unloaded, disassemble your firearm, clean and properly lubricate it per the instructions, cycle the action a few times to ensure all parts are moving freely. Head to the range and run some high-quality ammunition through your firearm. Typically you will see performance and reliability become consistent after the first initial uses of the firearm. Clean and lubricate as needed during break-in.

Shotguns typically will require 50-100rds of ammunition, we recommend a heavy load of 1oz or heavier for break in.

The design of the Turkish T-1919 pattern magazine allows it to be “over-inserted” in certain models of firearms. This can cause feeding issues and/or damage to the magazine. To mitigate this, when inserting the magazine, it is not necessary to seat the magazine with force. Pulling downward on the magazine will often engage the magazine catch in the proper manner if the magazine was over-inserting during initial loading.

If the magazine is stuck, before attempting to remove it, ensure there are no live ammunition in the firearm. To remove any live ammunition from the magazine, you can remove the base plate by pressing in the “O” and sliding it forward (The Star is just decorative and doesn’t need to be pushed to remove the base). Once it has been cleared, hold the magazine release button and pull down on the magazine.

If you have not found any answers that you had in the above section, then please fill out the form below or call us at:

(865) 604-6894

(Monday through Friday 8:30am – 4:30pm)